Comprehending Gauge Fillet Weld: A Comprehensive Overview for Welders

Comprehending Gauge Fillet Weld: A Comprehensive Overview for Welders

Blog Article

Innovative Techniques to Fillet Weld Inspection and Screening: Enhancing Weld High Quality and Compliance Standards

In the world of welding, the top quality and stability of fillet welds play a crucial function in ensuring the structural strength and dependability of various industrial components. With the continuous drive for enhanced effectiveness and compliance with rigorous criteria, the exploration of cutting-edge strategies to fillet weld examination and screening has come to be vital.

Advanced Non-Destructive Testing Approaches

Making use of modern innovations, advanced non-destructive testing methods play a crucial duty in guaranteeing the stability and quality of fillet welds. These methods, such as phased selection ultrasonic screening (PAUT) and magnetic particle screening (MPT), offer detailed insights into the weld's interior structure without creating any type of damage to the material. PAUT, for circumstances, makes use of numerous ultrasonic aspects to inspect the weld from numerous angles, offering a comprehensive visualization of possible defects like lack of combination or cracks.

By employing these sophisticated non-destructive screening strategies, weld examiners can precisely examine the quality of fillet welds, guaranteeing compliance with industry criteria and guidelines. The capacity to detect imperfections early on not only enhances weld top quality however likewise avoids costly rework or failings in structural honesty, underscoring the relevance of these cutting-edge screening techniques in welding inspections.

Robotics and Automation in Evaluation

The assimilation of robotics and automation has actually transformed the evaluation process for fillet welds, improving effectiveness and precision in high quality assessment. Robotics use accurate control and repeatability in examining welds, guaranteeing regular and trusted outcomes. Automated systems can be set to follow details assessment courses, ensuring thorough coverage of welds and reducing the danger of human error.

Robotic examination systems furnished with sophisticated sensors can identify and gauge weld features with high accuracy, offering thorough data for analysis. These systems can identify issues such as fractures, absence of combination, and porosity, allowing prompt rehabilitative actions to be taken. In addition, robotics and automation allow for real-time information collection and evaluation, offering instant comments to operators and assisting in fast decision-making procedures.

Furthermore, the use of robotics and automation in fillet weld evaluation improves general efficiency by reducing examination times and increasing evaluation throughput. By simplifying the examination procedure, producers can make sure weld quality and compliance requirements are satisfied efficiently, ultimately causing cost savings and boosted item top quality.

Utilizing Artificial Intelligence for Analysis

Expert system plays an essential role in enhancing the efficiency and accuracy of analysis in fillet weld inspection procedures. By utilizing the power of AI, assessors can enhance the analysis of weld quality and compliance requirements, resulting in a lot more specific and trustworthy outcomes. AI formulas can quickly process large amounts of data from weld evaluations, finding problems or variances that may be challenging to recognize with the nude eye. This advanced modern technology enables real-time surveillance of weld quality, permitting immediate corrective actions to be taken if any kind of problems are detected.

In addition, AI systems can gain from past evaluation information, continually enhancing their capability to determine possible problems and variances in fillet welds. This adaptive knowing ability enhances the general quality control process, minimizing the possibility of human error and making sure that welds meet the called for standards. By integrating expert system into fillet weld evaluation, markets can accomplish greater degrees of performance, consistency, and compliance in their examination techniques.

Portable Tools for On-Site Assessment

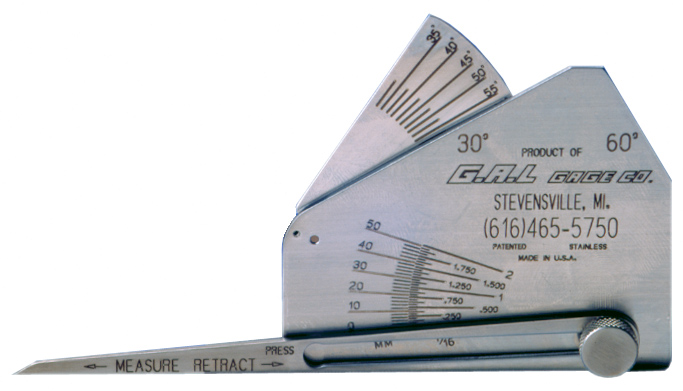

Enhancing field inspection performance, the adoption of mobile devices transforms on-site assessment processes for fillet welds. These tools supply adaptability and convenience, enabling examiners to perform extensive evaluations in various locations, including challenging or remote environments. Mobile tools such as ultrasonic screening gadgets, magnetic particle examination equipment, and electronic radiography systems give real-time data and high-resolution imaging capabilities, allowing quick decision-making and prompt comments on weld top quality.

One significant advantage of portable devices is their ability to streamline evaluation treatments, minimizing downtime and boosting overall productivity - Gauge Fillet Weld. Inspectors can conveniently move these devices to different job websites, eliminating the need for transporting hefty equipment or components to off-site facilities. In addition, the transportability of these devices advertises cost-effectiveness by reducing transport expenses and increasing evaluation timelines

Moreover, the use of mobile devices for on-site assessment advertises aggressive quality assurance procedures, as assessors can promptly recognize and attend to any kind of potential welding flaws or discrepancies. By integrating these cutting-edge technologies right into on-site assessment methods, welding experts can make sure compliance with sector standards and enhance weld high quality, ultimately resulting in boosted architectural stability and security in various welding applications.

Combination of Information Monitoring Systems

Having actually enhanced on-site inspection processes via the application of portable devices, the following stage includes the smooth integration of information management systems to better boost effectiveness and data evaluation abilities in fillet weld evaluation and testing. By integrating information management systems right into the evaluation procedure, companies can simplify information collection, storage, and analysis. This combination enables real-time surveillance of weld top quality, instant identification learn the facts here now of issues, and prompt decision-making to fix any kind of problems that may develop during the examination procedure.

Information management systems play a crucial function in streamlining evaluation data, assisting in very easy gain access to for authorized employees, and guaranteeing information honesty and safety and security. Via the combination of these systems, inspectors can create detailed reports, track historical data for fad evaluation, and boost total procedure effectiveness. The integration of information monitoring systems enables smooth communication between various stakeholders involved in the evaluation procedure, promoting partnership and improving overall top quality control procedures. Eventually, the combination of information management systems offers to boost the requirements of fillet weld assessment and testing, making certain compliance with sector policies and enhancing weld high quality.

Final Thought

Finally, Home Page cutting-edge techniques to fillet weld inspection and screening have actually dramatically boosted weld high quality and conformity standards. Advanced non-destructive screening approaches, robotics, automation, synthetic intelligence, portable tools, and data monitoring systems have transformed the means weld evaluations are carried out. By using these technologies, markets can guarantee that welds meet the required quality criteria and regulations, ultimately improving total efficiency and security in welding processes.

Having optimized on-site evaluation procedures through the application of portable devices, the following stage entails the smooth assimilation of information management systems to better enhance efficiency and information analysis abilities in fillet weld evaluation and screening. Ultimately, the combination of data administration systems offers to elevate the criteria of fillet weld inspection and testing, guaranteeing compliance with industry laws and enhancing weld quality.

Report this page